-

Torba paketleme makinesi

-

Granül Paketleme Makinası

-

Sıvı Paketleme Makinası

-

Toz Paketleme Makinası

-

Mini Doypack Paketleme Makinası

-

Çay poşeti paketleme makinesi

-

Kahve Paketleme Makinası

-

dikey paketleme makinesi

-

Akış Paketleme Makinası

-

Stand Up Poşet Paketleme Makinası

-

Döner Vakum Paketleme Makinası

-

Dolum Makinesi

-

Yatay Doypack Paketleme Makinası

-

Hazır Çanta

-

Paketleme Makinası Aksesuarları

-

dolgu ve kaplama makinesi

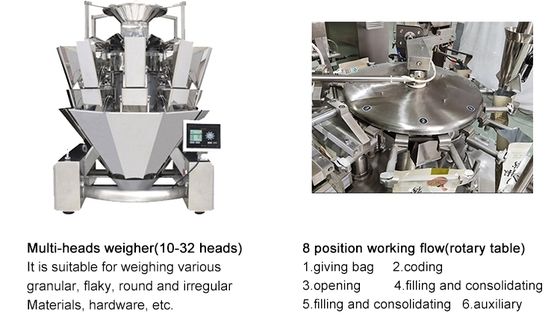

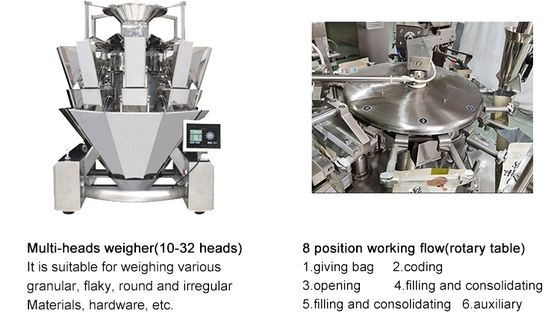

Kediler için evcil hayvan ürünleri ambalajlama makinesi kedi yemeği köpek yemeği tatlıları toz temizleyici cihazlı dondurma ürünleri

| Tip | Otomatik ambalaj makinesi | Ürün adı | gıda granül çok istasyonlu ambalaj makinesi |

|---|---|---|---|

| boyut (l*w*h) | L1900*W1400*H1450 | Ağırlık (kg) | 1300 |

| Gerilim | 110V 220V 380V 50Hz/60Hz | Üretim kapasitesi | 20bag/dk, 50bag/dk, 30bag/dk |

| Vurgulamak | Toz temizleyicisi olan kedi çöpü paketleme makinesi,Dondurulmuş tatlılar için köpek maması paketleme makinesi,Evcil hayvan ürünleri için granül paketleme makinesi |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Kedilerin çöpü, kediler için yiyecek, köpekler için yiyecek, tatlılar ve dondurma ile kurutulmuş ürünler için evcil hayvan ürünleri ambalajlama makinesi toz temizleme cihazı ile

"Önce yapılmış çuval kedi çöpü ambalaj makinesi" evcil hayvan malzemeleri üretim endüstrisinde çok önemli ve yaygın bir ekipmandır.Özellikle kedi çöpünü otomatik olarak doldurmak için tasarlanmış., bentonit, tofu çöpü, kristal çöp ve karışık çöp gibi, önceden hazırlanmış ambalaj torbalarına.

I. Önceden yapılmış bir çuval kedi çöpü paketleme makinesi nedir?

Bu, arka tarafında sıklıkla tekrar kapanan bir fermuar (kurulu bir poşet) bulunan önceden hazırlanmış torbalar kullanan otomatik bir ambalajlama cihazıdır.Çantayı seç -> Çantayı aç -> Doldur -> Kompakt (Farklı) -> Hava boşalt / Dükkan -> Bitiş Ürün çıkışı.

Başka bir yaygın makineye benzer bir prensiple çalışır, "torba veren ambalaj makinesi", ancak kedi çöpünün özelliklerine (toz, değişen parçacık boyutları,Kararsız toplu yoğunluk, vb.).

II. Ana Özellikler ve Avantajlar

1Estetik açıdan hoş ambalaj: Önceden hazırlanmış torbalar genellikle muhteşem bir şekilde basılır ve doğrudan satış noktası ambalajı olarak kullanılabilir ve ürünün kalitesini artıran çekici bir görünümle kullanılabilir.

2Yüksek Otomasyon Derecesi: Torba toplama işleminden bitmiş ürün çıkışına kadar olan süreç tamamen otomatiktir, işgücünü önemli ölçüde tasarruf eder ve üretim verimliliğini artırır.

3.Zip kapama fonksiyonu: Bu, kedi çöpü ambalajlama için gerekli bir fonksiyon. Makine, fermuarı doğru bir şekilde açar ve ısılı olarak kapatır.mühür bütünlüğünü sağlamak ve tüketicinin çoklu kullanımını kolaylaştırmak.

4Güçlü uyarlanabilirlik:

Çanta Türleri: Arka kısımlı ayakta duran poşetler, dört taraflı mühürlü ayakta duran poşetler ve el poşetleri gibi çeşitli poşet türlerini taşıyabilir.

Malzemeler: Farklı besleme cihazlarını değiştirerek (makara besleme, yerçekimi besleme, titreşim besleme gibi), bentonit granülleri gibi farklı fiziksel özelliklere sahip kedi yuvalarına adapte olabilir,Uzun tofu kedi çöpleri, ve ince kristal kum.

5Entegre sıkıştırma ve hava boşaltma fonksiyonları:

Sıkıştırma: İçindeki çöpü sıkıştırmak için torbayı titreştirir, nakliye sırasında torbanın şişmesini önler ve daha yoğun bir paketleme sağlar.

Hava tahlili: Paketi daha kompakt hale getiren ve depolama ve taşıma alanını tasarruf eden bir hava tahlili aygıtı, seçme olarak poşetten hava çıkarmak için donatılabilir.Özellikle bentonit çöpü için uygundur.

6.Tam ölçüm: Ticari şartlara uygun olarak, çanta başına tutarlı bir ağırlık sağlamak için yüksek hassasiyetli elektronik ölçekler (örneğin, ağırlık-doldurma tipi) veya hacim ölçümü kullanır.

III. Temel İş Akışı

1Çanta yükleme: Bir robot kolu otomatik olarak çanta depolama dergisinden önceden hazırlanmış bir çanta alır.

2Çanta Açma: Çanta ağzını açmak ve doldurma nozelinin üzerine yerleştirmek için emici fincanlar veya saplar kullanılır.

3Doldurma: Ölçülen kedi çöpü dolma nozluyla torbaya düşer.

4Sıkıştırma/Düzleştirme: Doldurma sırasında veya sonrasında, yüksek frekanslı titreşim çöpü sıkıştırır ve düzleştirir.

5. Hava tahlili (ihtiyaçlı): Bu işlev yapılandırılmışsa, çanta içindeki hava bu aşamada çıkarılır.

6.Sıcaklıklı Sızdırma: Çanta ağzı, iç fermuar mühürü ve dış çanta ağzı mühürü dahil olmak üzere sıcaklıklı.

7Çıktı: Bitmiş, mühürlenmiş torba bir bant ile taşınır ve tarihini / parti numarasını yazdırmak için bir etiketleyiciye veya kodlayıcısına bağlanabilir.

IV. Temel ekipman bileşenleri

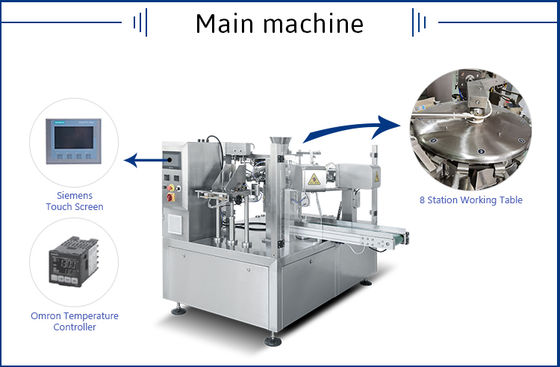

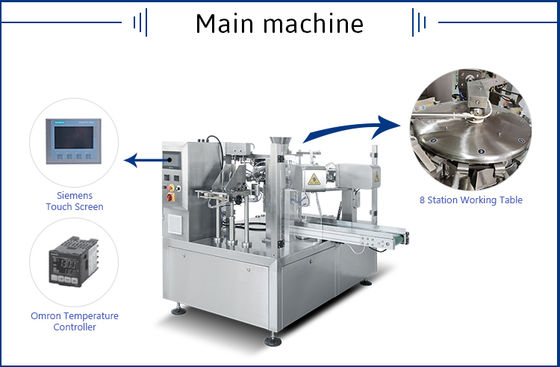

1Ana çerçeve ve kontrol sistemi: PLC + dokunmatik ekran HMI, ekipmanın beyni.

2Çanta yükleme mekanizması: Servo motorlu robot kolu, çantayı doğru bir şekilde seçmek ve açmakla sorumludur.

3Ölçme Sistemi: Genellikle en yüksek doğruluğu sunan ve çöplük toplu yoğunluğundaki değişikliklere adapte olan ağırlık dolu bir hopper ölçeği.

4Doldurma sistemi: Bir depolama hoperi, besleme mekanizması (örneğin, vida, kapı) ve toz geçirmez tasarım içerir.

5.Dikleştirme Cihazı: Genellikle dolgu istasyonunun altında veya yanında bulunan yüksek frekanslı vibratör.

6. Hava tahliye sistemi: Vakum pompası ve emici nozel.

7.Sıcaklık Sızdırma Sistemi: Hem fermuar hem de torba ağzının güvenli bir mühürlenmesini sağlamak için ısıtma plağı ve soğutma plağı.

8Taşıyıcı kemer: Çeşitli çalışma istasyonlarını birbirine bağlar ve torbaları ve bitmiş ürünleri taşır.

Makine özellikleri:

| Ürün | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| PaketlemeHız | Paketleme filminin kalitesine,paketleme malzemelerine,paketleme ağırlığına vb. bağlı olarak MAX 60 torba/dakika. | ||

| Çanta boyutu | (L) 100-300mm (W) 70-200mm | (L) 100-350mm (W) 130-250mm | (L) 150-450mm (W) 200-300mm |

| Çanta türü | Hazır çantalar, ayağa kalkan çantalar, dört taraflı kapalı çantalar, üç taraflı kapalı çantalar, özel şekilli çantalar. | ||

| Ağırlık aralığı | 10g-1kg | 10g-2kg | 10g-3kg |

|

Ölçüm doğruluk |

* ölçüm ekipmanına ve malzemelerine bağlı olarak ± 0,5 ~ 1%. | ||

| En fazla torba genişliği | 200 mm | 250 mm |

300 mm |

| Gaz tüketimi | 0.8Mpa 0.3m3/min (kullanıcı tarafından tedarik) | ||

| Toplam Toz/Voltaj | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Hava kompresörü | En az 1CBM | ||

| Boyut | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Makine ağırlığı | 1300kg | 1400 kg | 1500 kg |

| Çalışma akışı | Verme torbası→Kodlama→Açma torbası ((veya Açık fermuar torbası)→Doldurma→Yardımcı→Egzoz→Sıcaklık mühürlenmesi→Formasyon ve çıkış ürünleri. | ||

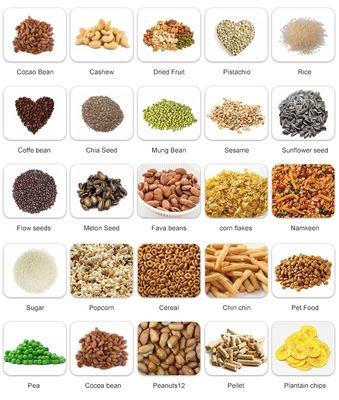

| Uygulanabilir kapsam | Granüler tür: kristal monosodyum glutamat, granüler ilaç, kapsül, tohumlar, kimyasallar, şeker, tavuk esansı, kavun tohumları, fındık, pestisit, gübre vb. | ||

(İhtiyaçlarınıza göre özel özel hizmetler sağlayabiliriz!)

![]()

![]()

![]()

![]()